Making Aleppo soap is an art that has remained largely unchanged for centuries.

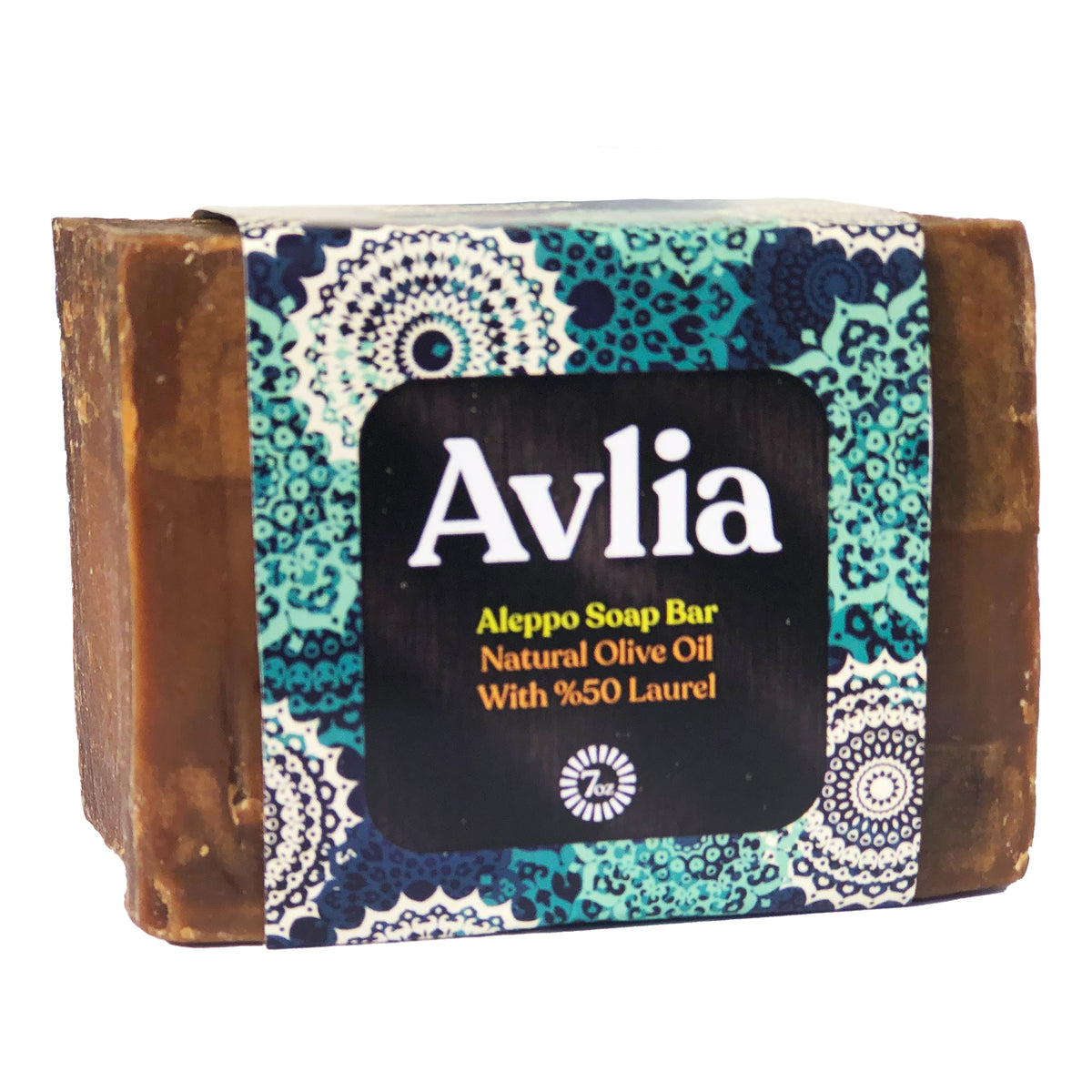

Explore Handcrafted Aleppo Soap

Traditional Method

-

Olive oil is gently heated with water and lye in large vats.

-

Laurel oil is added toward the end of the process.

-

The soap mixture is poured onto the factory floor, smoothed, and left to cool.

-

Bars are hand-cut and stamped.

-

Curing lasts 6–9 months, allowing the soap to harden and develop its signature golden exterior and green interior.

Modern Shortcuts

Some modern manufacturers speed up curing using heat or chemical accelerants, which can reduce quality. While faster, these soaps may lack the natural mildness of traditionally cured bars.

Avlia’s Approach:

We follow traditional methods, ensuring each bar is fully cured to achieve maximum gentleness and longevity.